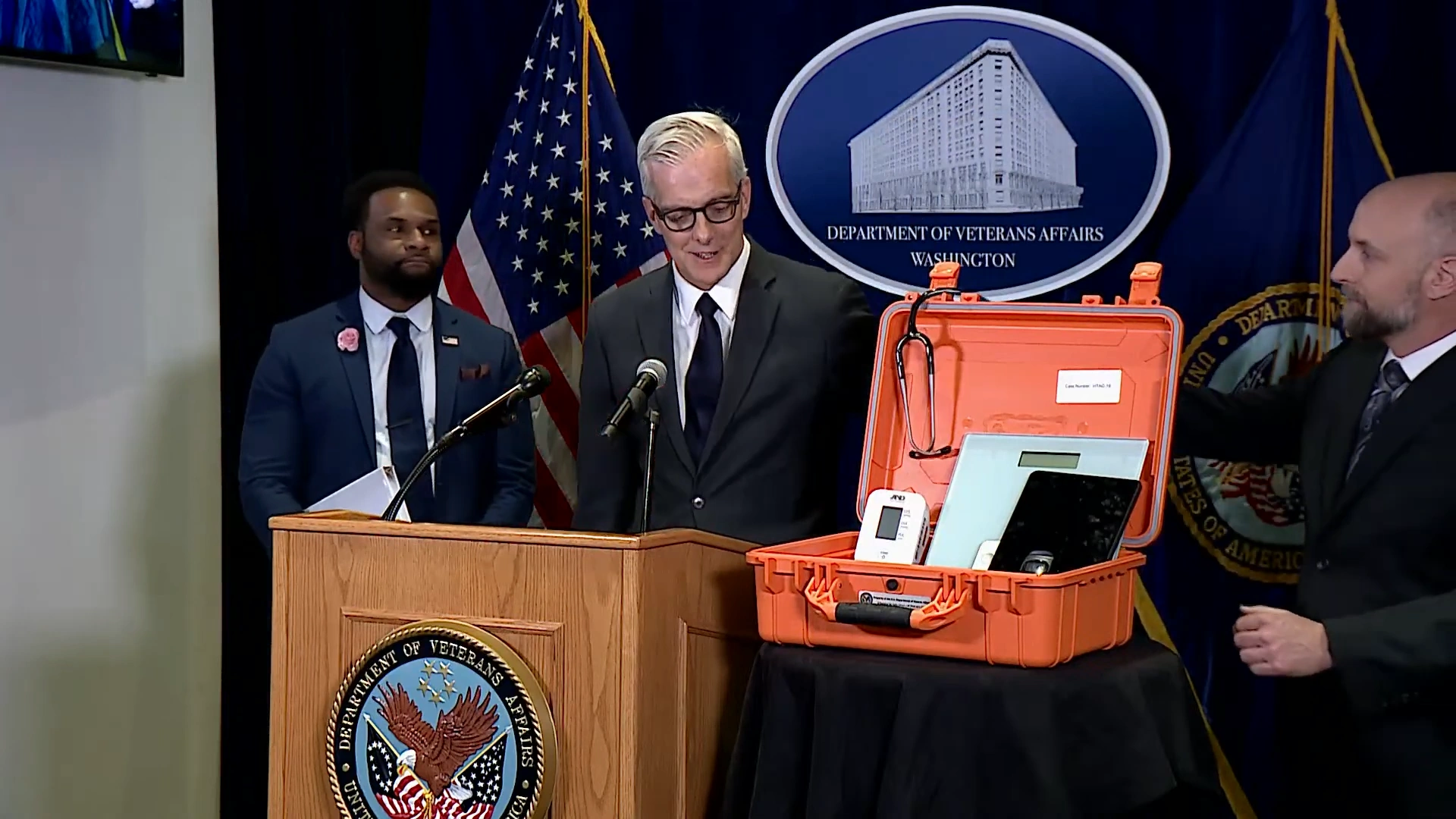

//Telehealth Equipment

HermTac.

Internet XaaS

Connectivity programs

to boost your mission

We keep our partners connected so they can deliver care from the battlefield to the home.

Hardware

Bespoke portable equipment.

Data

Unlimited fixed price global data.

VPN

Gov Cloud hosted VPN servers.

Management

Support, advice, & fleet management.

All The

Internets

We manufacture bespoke network equipment.

Available in both purchase & subscription models.

Highly portable battery powered SDWAN bonding internet cases are our jam.

ROCIT

0

Pounds

0

Modems

0

VPN Mbps

0

National Awards

//How We Work

How We Work

Consulting Process

We do not fear calculated risks. Let us do the messy innovation work.

-

Ideate

01.Discuss

Co-ideate & discover solutions for you organization's pain points.

-

Design

02.Engineering with a purpose.

Protyping, trials and small batch runs with feedback built-in.

-

Enact

03.Implement

Manufacture as needed and enact aggreed upon solutions with sustainment and manageability in mind.

Projects//

2020

2021

2022

Partners